“How easy 3D printing can be and how quickly ideas can develop” Uwe Bodenschatz from KulturWerk Schneeberg e.V. in an interview

Uwe Bodenschatz is a qualified wood designer and has been active for many years in the fields of design, digital manufacturing, and modern production technologies. Professionally, he gained experience in sales and product design, including as a regional sales manager in the furniture industry. Today, he is a board member of KulturWerk Schneeberg e.V. in the Ore Mountains, an organization dedicated to promoting art, design, and innovative craft culture. As part of the European FashionTEX project, Uwe Bodenschatz was a member of the expert team and led workshops in the makerspace on topics such as 3D printing, laser cutting, and digital production techniques. With his experience in design practice and digital workshop culture, he supported the students in experimenting with new technologies, from initial printing attempts to complex prototypes.

Mr. Bodenschatz, you guided the students in the area of 3D printing. What developments did you observe during the makerspace?

Uwe Bodenschatz: Most of them had little experience with 3D printing at the beginning; some had actually never printed anything before. However, during the workshop, everyone created at least one object and understood the basic processes. It was particularly exciting to see that about 75 percent of the students developed accessories using 3D printing. Some even made 3D printing the central element of their design.

Were there any particular “aha” moments?

Uwe Bodenschatz: Oh yes, many! Perhaps the most important moment for many was realizing how simple and fast the process can actually be and how quickly developments emerge once you get started. This immediate sense of accomplishment really motivated many of them.

From your perspective, how did the makerspace contribute to collaboration between universities, disciplines, and cultures?

Uwe Bodenschatz: It was a real catalyst for networking, both among the students and among the participating experts and organizations. There were many intensive discussions, creative exchanges, and new contacts across national and disciplinary boundaries.

Were there any moments when the students personally surprised or inspired you?

Uwe Bodenschatz: Yes, several times. Some contributed very ambitious ideas, and others surprised me with completely new technological approaches. This combination of creativity and curiosity was truly inspiring.

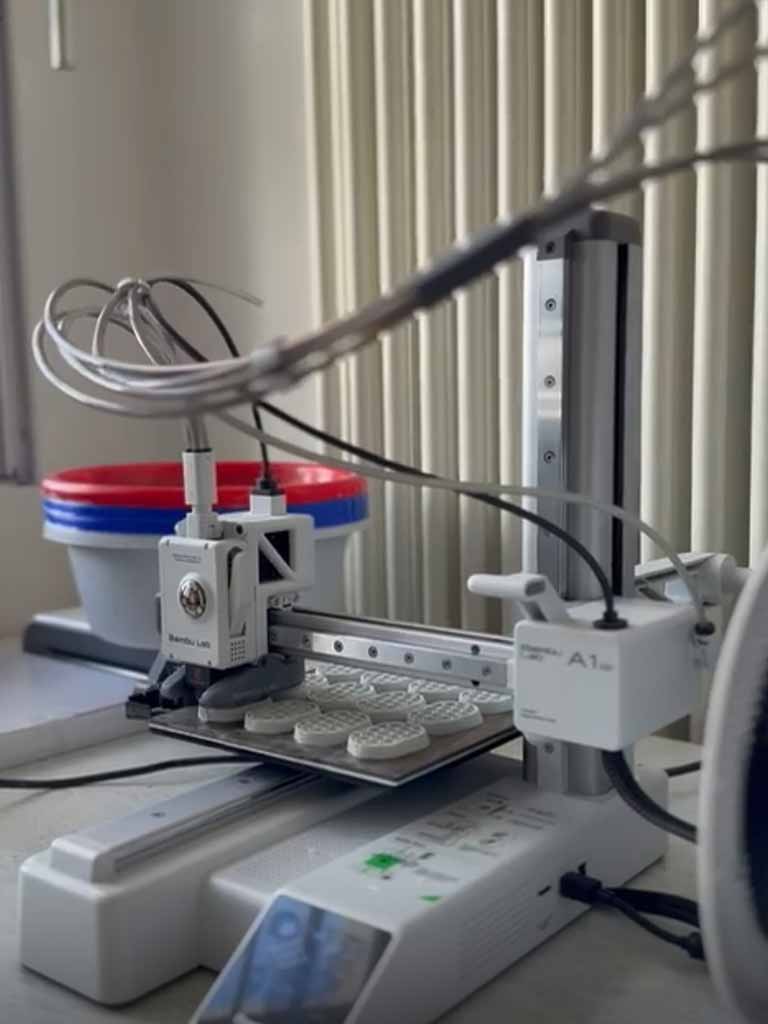

Which technical tools were used most intensively?

Uwe Bodenschatz: Clearly, 3D printing. Many had to acquire the necessary software knowledge for this, which they managed excellently. The laser cutter was also frequently used; it was more accessible for many because it works more intuitively.

Which results impressed you the most personally?

Uwe Bodenschatz: Actually, all of them, but Joanna’s work, where she printed directly onto her entire garment using TPU material, was technically very demanding. The various 3D-printed shoe projects—three in total—were also fascinating. They showed how courageous and experimental the students were in their work.

What was the biggest challenge in the process?

Uwe Bodenschatz: Definitely the time. In the end, it got very tight, and we had to invest many extra hours to complete all the projects. Some works were even finished after the official end of the workshop.

What, in your opinion, should be retained or further developed in future makerspaces?

Uwe Bodenschatz: The format itself is excellent; it offers a unique learning and exchange platform. However, if you expect the same output as here, the workshop should last at least three weeks. That would create more room for experimentation, mistakes, and refinement.

Are there any technical improvements you would recommend?

Uwe Bodenschatz: The equipment was very good overall. For larger textile projects, a larger laser cutter would be helpful to cut entire lengths of fabric. Furthermore, we could expand our 3D printing capabilities, for example, with additional printers or new technologies such as laser sintering with flexible materials, which would be very exciting in a textile context.

When you think about the future of the project – where do you see the greatest potential?

Uwe Bodenschatz: In the interplay of technology, design, and sustainability. The makerspace has shown how powerfully young designers can think, research, and create when given the right tools. That is the future of fashion, and it starts here.