“Finished is better than perfect” – August Oster on learning, technology and community in the makerspace.

The 22-year-old fashion student from the Amsterdam Fashion Academy talks about how working in the makerspace has shaped him – between digital precision, hands-on experimentation, and a strong sense of community.

August Oster: You are in your third year of the Bachelor’s degree program in Fashion Design at the Amsterdam Fashion Academy. What new skills or insights have you gained in the makerspace, beyond the technical aspects?

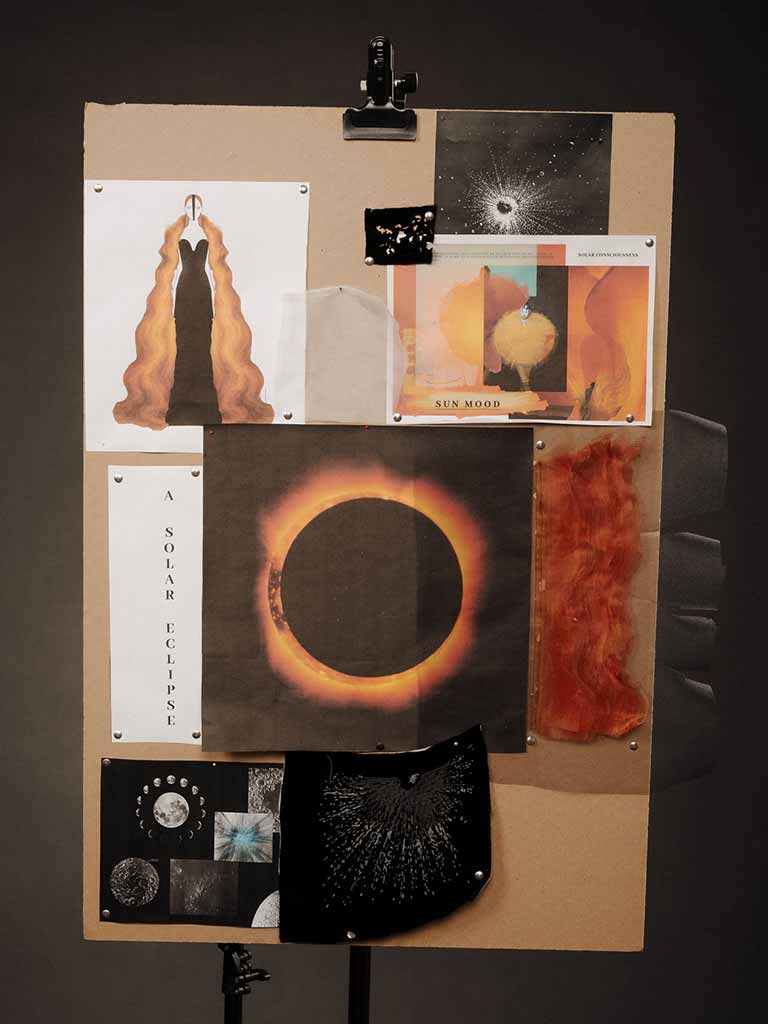

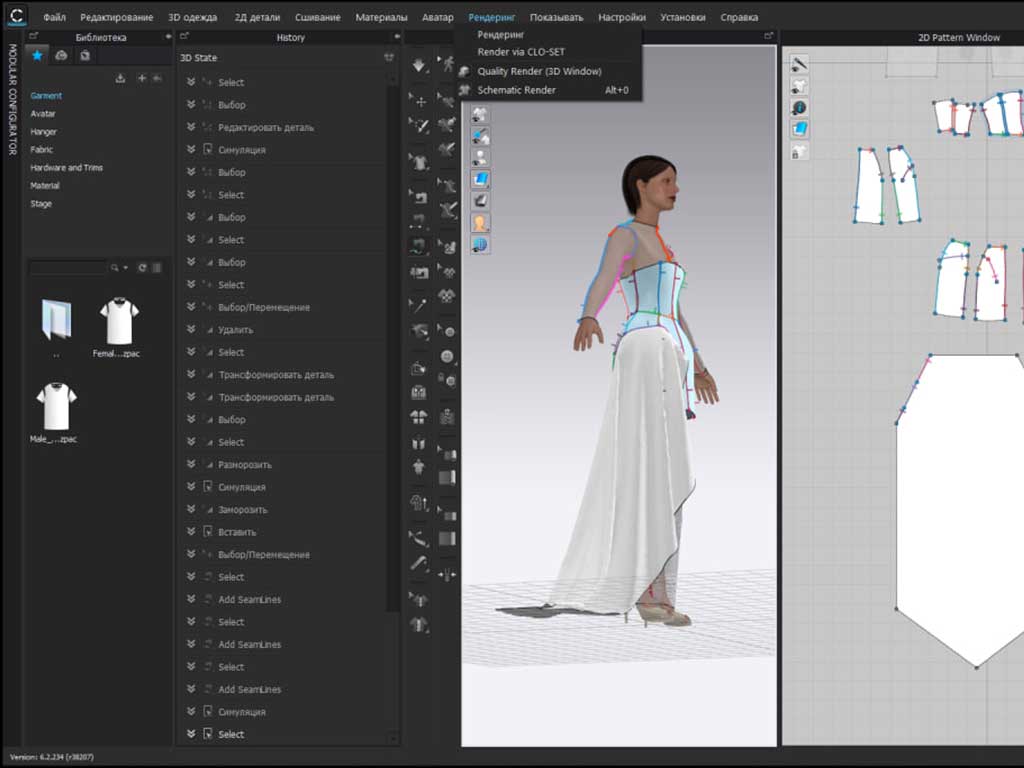

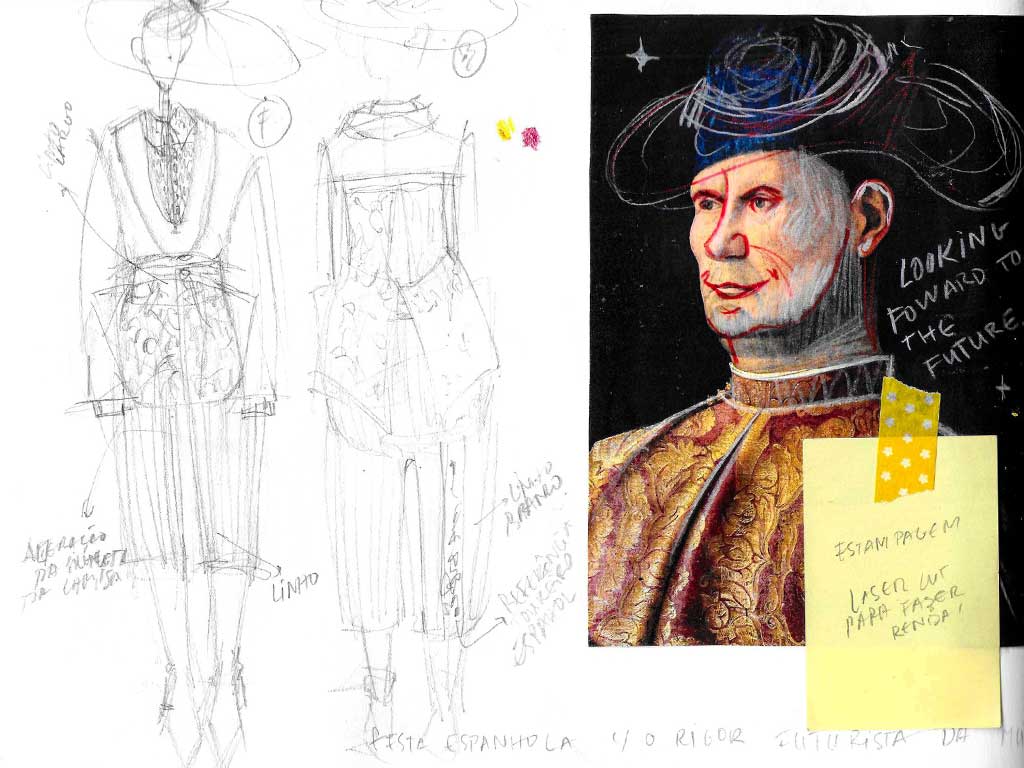

August Oster: In the makerspace, I significantly improved my digital fashion work. I learned how to create better materials and textures, set the right physical properties, and conduct more reliable simulations. I also understood how important clean files are and how to prepare and test settings for laser cutting, 3D printing, knitting, and embroidery. Working in a shared space showed me how crucial communication is: planning machine times, making clear agreements with the staff, documenting settings, and giving or receiving feedback quickly. Through the design thinking approach, I learned to test in short cycles, learn from mistakes, and see limitations as a creative opportunity. Living and working together in Schneeberg was something very special – like a creative bubble full of fashion enthusiasts. This built trust and encouraged us to conduct bold but well-considered experiments.

Was there a moment when you thought, “This is an ‘aha’ moment” or “This is a truly innovative approach”?

August Oster: Absolutely, that was with the 3D printer. I had designed a mask that looked perfect in CLO3D, but the print didn’t fit my head at all. That’s when I realized: what works virtually doesn’t necessarily work in reality. Since then, I measure the head precisely, print small test pieces – for example, the nose or cheek area – add some leeway, and only then print the complete object. This saves time and ensures that the fit is really right.

Did you make any new contacts or connections with other students or universities in the makerspace?

August Oster: Yes, that was one of the highlights. I met many great people, and we started a small chat group to stay in touch. The bunker party in particular was a great icebreaker and left lasting memories.

What was your biggest personal challenge while working in the makerspace – and how did you overcome it?

August Oster: Definitely the time pressure and my perfectionism. I set strict deadlines for myself and did small tests before starting anything big. I also applied the 80/20 rule: first make it functional, then do a quick polish. Another trick was asking others for a quick check before I continued. This reduced rework and helped me prioritize “finished” over “perfect.”

What specific result or insight did you gain from working on your avatar or outfit?

August Oster: I learned to keep the big picture in mind – to assess the silhouette and movement first before getting lost in details. I stay flexible, do small tests, compare CLO3D with real bodies, and note what works. This saves a tremendous amount of time and strengthens the final result.

Was there a moment that particularly inspired or surprised you?

August Oster: 3D printing really excited me. The variety of filaments, from wood and marble looks to metallic and flexible options, is fascinating. Just changing the spool changes the texture and weight without having to adjust the file. If a test works, you can immediately produce multiple pieces. This inspires me to work more modularly in the future and experiment more with surface textures.

Which technical tools did you work with the most – and what did you learn from using them?

August Oster: Mainly with CLO3D, Illustrator, the laser cutter, the 3D printer, and a little bit with embroidery software. In CLO3D, I checked the silhouette and fit and realistically adjusted fabric properties. In Illustrator, I cleaned up vector files, correctly set line types for cutting, and exported reliable DXF or SVG files. With the laser cutter, I learned to conduct small tests for power and speed, consider the kerf, and incorporate fold lines. The embroidery software showed me how much stitch types and density influence the result.

My most important lesson: always do small, labeled test samples and prepare clean files – this saves an enormous amount of time and makes the transition from digital design to real materials much easier.

What result of your work in the Makerspace are you particularly proud of?

August Oster: My embroideries. They didn’t make it into the final outfit, but the sample patterns were clean and expressive. I could see how small changes completely alter the effect. These designs are a foundation on which I want to continue building; they feel like my personal signature.

How do you want to continue after the Makerspace?

August Oster: I want to finish my studies and further expand my portfolio. My goal is to start my own demi-couture brand in Amsterdam that combines digital tools with meticulous handwork.

Before that, I plan to do internships at fashion companies to better understand production, sourcing, and business processes. And I’ll stay in touch with the people from the Makerspace – we exchange feedback, files, and tips.

Are there any ideas or projects that you would like to develop further, whether for the Holo Show or other areas?

August Oster: Yes, I want to continue working on the connection between digital and real – improving the fit, developing a consistent design language with textures and embroideries, and integrating AR or holographic elements. I also want to test more sustainable, repair-friendly methods.

What was your biggest personal gain from your time in the Makerspace?

August Oster: Clearly: self-confidence and community. I learned to ask for help, give feedback, and embrace new things. My time in Schneeberg took me out of my comfort zone and showed me that I can do much more than I thought – with new friendships, fresh ideas, and the courage to tackle bigger projects.